output: Upto 60 cartons per minute depending on product charatersitics and carton size.

Manpower:One operator for running the machine loading of cartons in the magazine and for filling glue units.

Cartons Out feed: Height to carton base: 1050mm

Cartons Dimension:

| MIN | MAX | |

| Length | 60 | 150 |

| Width | 22 | 108 |

| Length+Width | 94 | 215 |

| Height | 83 | 230 |

Size Change :All carton dimension can be charged within given range.

Electric supply:Standard 440/220 volt. 3-phase, 50Hz.

power required:6-8 KW depending on equipment.

Floor space:2.2*3.4 (Without pressure converyor) weight: Approx. 1700 kg

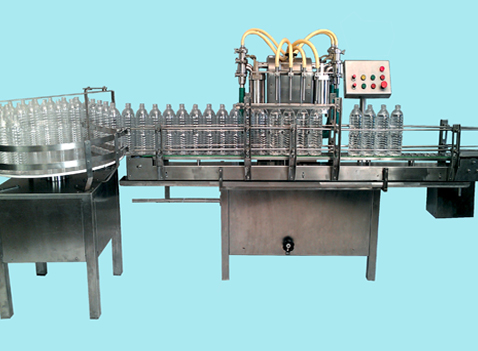

Filling: Filling can be done only at 12 or more stations. All typr of filler can be used.

Lined material: Liner material is specifically selected form a wide range of lamination depending on the product protection required.

output: Upto 15 cartons per minute depending on product charatersitics and carton size.

Manpower:One operator for running the machine loading of cartons in the magazine and for filling glue units.

Cartons Out feed: Height to carton base: 1050mm

Cartons Dimension:

| MIN | MAX | |

| Length | 60 | 150 |

| Width | 22 | 108 |

| Length+Width | 94 | 215 |

| Height | 83 | 230 |

Size Change :All carton dimension can be charged within given range.

Electric supply:Standard 440/220 volt. 3-phase, 50Hz.

power required:6-8 KW depending on equipment.

Floor space:2*2 (Without pressure converyor) weight: Approx. 1300 kg

Filling: Filling can be done only at 1.2 or more stations. All typr of filler can be used.

Lined material: Liner material is specifically selected form a wide range of lamination depending on the product protection required.

Precise and accurate dosing, and reliable product flow makes this a proven filling system. Product protection system like "neutrafill" can be synchronized with the Auger doser to achieve less than 1% residual oxygen levels. Excellent for products like flour, spice, coffee powder etc.

Fast, precise and maximum weight accuracy is achieved by this system. Multihead weighers can be attached to the packaging machines to achieve the perfect package weight. Best for products like snack foods,dry fruits, candies etc.

The machine is fully automatic P.L.C. controlled. It has a steel frame with four adjustable feet to allow a maximum of clearance for cleaning the base. Above the machine-working surface, the height of which is 800 to 850 mm, the following units are placed.

Jar transport unit, complete with a conveyor belt.

Basic machine suitable to fill 50ml to 1 litre jars

Above the machine-working surface, which height is 800 to 850mm, the following units are placed.

S.S.304 steel Structure.

It depends on the fill size and viscosity of the products.

We are an able manufacturer,exporter and supplier of a wide range of packaging products comprising:

⋅ Lined Cartons (CEKA PACK)

⋅ Mono Cartoons

Packing range 5kg to 100kg.

Bag type Open Mouth Type

Speed 600 Bags/ hr, depending on the products.

& bulk density

Filling systemGravity Feeder

Automatic Gripping

Load Cell Based

Electronics Controlled(Imported)

Suitable for Sugar: Fertilizer,Rice, Soda Ash, PVC Granules

Technical specification are subjected to change without notice.

output: Upto 60 cartons per minute depending on product charatersitics and carton size.

Manpower:One operator for running the machine loading of cartons in the magazine and for filling glue units.

Cartons Out feed: Height to carton base: 1050mm

Cartons Dimension:

| MIN | MAX | |

| Length | 60 | 150 |

| Width | 22 | 108 |

| Length+Width | 94 | 215 |

| Height | 83 | 230 |

Size Change :All carton dimension can be charged within given range.

Electric supply:Standard 440/220 volt. 3-phase, 50Hz.

power required:6-8 KW depending on equipment.

Floor space:2.2*3.4 (Without pressure converyor) weight: Approx. 1700 kg

Filling: Filling can be done only at 12 or more stations. All typr of filler can be used.

Lined material: Liner material is specifically selected form a wide range of lamination depending on the product protection required.